Understanding Powder Coating

What is Powder Coating?

Powder coating is a finishing process that has gained immense popularity in recent years due to its durability and aesthetic appeal. Unlike traditional liquid paints, powder coating uses a dry powder applied electrostatically to the surface of a metal object. This powder is then cured under heat, typically around 350°F (about 177°C), forming a hard, protective layer that adheres strongly to the substrate. The result is a robust finish that is more resilient than conventional paint, which may chip, fade, or corrode over time.

Benefits of Powder Coating Over Traditional Painting

The advantages of powder coating are numerous. Firstly, it is highly resistant to chipping, scratching, fading, and wearing, making it ideally suited for automotive parts, outdoor furniture, and any other items exposed to the elements. Additionally, powder coating is environmentally friendly, as it releases fewer volatile organic compounds (VOCs) than traditional spray paints. This innovative process also minimizes waste; any overspray can be reclaimed and reused, often leading to a more efficient operation.

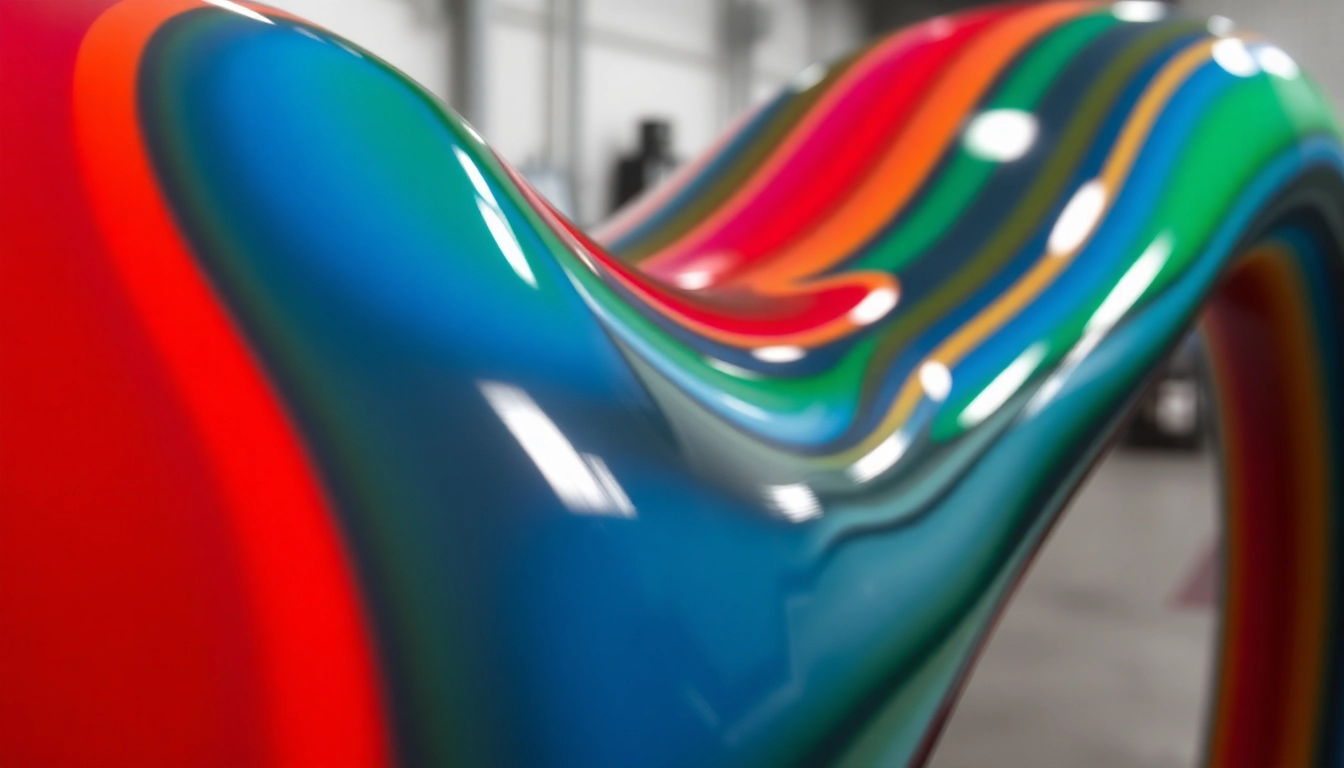

Furthermore, powder coatings are available in almost any color or texture, offering a level of customization that appeals to designers and homeowners alike. Unlike conventional paints that can require multiple coats for full coverage, powder coating typically achieves the desired thickness in a single application.

Common Applications of Powder Coating

Powder coating is versatile and suitable for a wide range of applications. Some of the most common uses include:

- Aerospace and Automotive: Parts such as wheels, frames, and brake calipers benefit greatly from powder coating due to its durability and protective qualities.

- Home Appliances: Items like refrigerators and washers often undergo powder coating to enhance appearance and protection.

- Furniture: Outdoor furniture is commonly powder coated to withstand various weather conditions without fading or rusting.

- Architectural Structures: Railings, fences, and doors are often powder coated to add visual appeal and longevity.

Choosing the Right Powder Coating Service in Birmingham

Evaluating Competitors: Local Options for Powder Coating Birmingham

When looking for powder coating services in Birmingham, it is essential to evaluate local providers based on their reputation, range of services, and customer feedback. Competitors such as Coyote Coating offer a wide array of options for custom powder coating, from automotive and motorcycle parts to lawn and patio furniture. Steel City Metal, also a key player in the Birmingham area, specializes in a variety of metal items from lamp posts to fences. Understanding what each provider can offer helps streamline your decision-making process.

Factors to Consider When Selecting a Service

Choosing the right powder coating service goes beyond just comparing prices; several factors need to be considered:

- Quality of Work: Look for customer reviews and past work samples to gauge the quality of their finishes.

- Experience: A well-established company usually possesses the necessary expertise and equipment to ensure high-quality results.

- Range of Services: Ensure the company can handle your specific needs, whether it involves custom colors, textures, or types of surfaces.

- Turnaround Time: Understand how long the service will take, especially if you have a deadline for your project.

Customer Testimonials: What Makes a Good Powder Coating Provider?

Customer testimonials can offer invaluable insights into a powder coating provider’s reliability and quality. A good provider often showcases multiple positive reviews on their website and third-party platforms. Look for comments on their responsiveness, professionalism, the quality of the finish, and how well they handle issues or complaints. Engaging directly with previous customers, if possible, can also provide more personal experiences that reinforce your decision.

Cost Factors for Powder Coating in Birmingham

Breaking Down the Average Costs

Understanding the costs associated with powder coating can help budget your project more effectively. The average cost for powder coating services typically ranges from $50 to $430 per item, with most customers spending around $170. This pricing can vary significantly based on factors such as item size, complexity, and the type of materials involved. For instance, larger items or those requiring intricate preparation might fall on the higher end of the spectrum.

Hidden Fees and Common Misconceptions

When assessing costs, be aware of potential hidden fees. Providers may charge additional costs for:

- Surface Preparation: Items that require extensive cleaning, sandblasting, or priming may incur extra charges.

- Color Changes: Changing from one color to another usually requires additional cleanup and setup.

- Custom Finishes: Specialty finishes or textures that require unique powders or processes might also lead to increased costs.

A common misconception is that powder coating is a one-size-fits-all solution; in reality, the specific needs of your project will dictate the price and level of service necessary.

Getting the Best Value for Your Investment

To ensure you receive the best value for your investment in powder coating, consider soliciting several quotes from different providers. Don’t hesitate to ask each for a detailed breakdown of their estimated costs. Look beyond just price—consider the reputation and quality assurance of the service. Investing in a reputable company can save you from costly repairs or rework down the line.

Technical Aspects of Powder Coating

The Powder Coating Process Explained

The powder coating process involves several critical steps to ensure a high-quality finish:

- Preparation: Items undergo thorough cleaning to remove dirt, grease, and existing coatings. This step can involve various methods, including sandblasting, chemical cleaning, or washing.

- Application: Once cleaned, the powder is applied using an electrostatic spray gun. The charged particles of the powder adhere to the grounded metal surface.

- Curing: The item is then placed in an oven where the powder melts and chemically reacts to form a durable finish as it cools.

Durability and Lifespan of Powder Coated Products

One of the most significant advantages of powder coating is its durability. Properly applied powder coatings can last anywhere from 10 to 25 years or longer under optimal conditions. Factors affecting the lifespan include exposure to UV light, chemicals, and physical abrasions. Regular maintenance and proper installation can significantly enhance the longevity of powder-coated surfaces.

Environmental Considerations in Powder Coating

The environmental impact of powder coating is considerably lower than that of conventional paint. The absence of VOCs helps reduce air pollution, and since unused powder can be reclaimed and reused, less waste is generated. Additionally, the powder coating process is efficient, resulting in fewer hazardous byproducts compared to liquid paint processes. This eco-friendliness makes powder coating an attractive choice for environmentally-conscious consumers and businesses alike.

Maintaining Your Powder Coated Surfaces

Best Practices for Cleaning and Maintaining Powder Coating Birmingham

To sustain the integrity and appearance of powder-coated surfaces, implement regular cleaning and upkeep. Here are some best practices to consider:

- Regular Cleaning: Use a mild detergent and water solution to clean surfaces regularly. Avoid abrasive cleaners that can scratch the finish.

- Immediate Spill Management: Wipe down any spills or stains immediately to prevent permanent discoloration or damage.

By incorporating these practices, you can maintain not only the aesthetic value of your powder-coated items but also their protective qualities.

Common Issues and How to Prevent Them

While powder coating is resilient, certain issues can arise:

– Fading: Prolonged UV exposure can lead to color fading over time. Using products with UV resistant properties during application can mitigate this risk.

– Chips or Scratches: While powder coatings are tough, impacts can still cause damage. Be cautious during handling and movement of coated items.

Understanding these common issues can help you take preventive measures to ensure your powder-coated surfaces remain in excellent condition.

When to Seek Professional Help for Repair

Despite proper maintenance, damage may occur requiring professional intervention. Signs it’s time to consult a professional include:

- Visible Damage Extensive Enough to Require Repair: If the damage impacts appearance or functionality, professional refinishing may be necessary.

- Persistent Stains or Corrosion: If cleaning does not restore the surface, it may require professional assessment or repairs.

By recognizing when to seek assistance, you can extend the life and functionality of your powder-coated products effectively.

Leave a Reply